Does your plant:

Bypass during peak flows?

Use more energy than you want?

Struggle to meet effluent permit limits?

Need to expand for growth?

Pacific Wastewater Optimization’s Focus

-

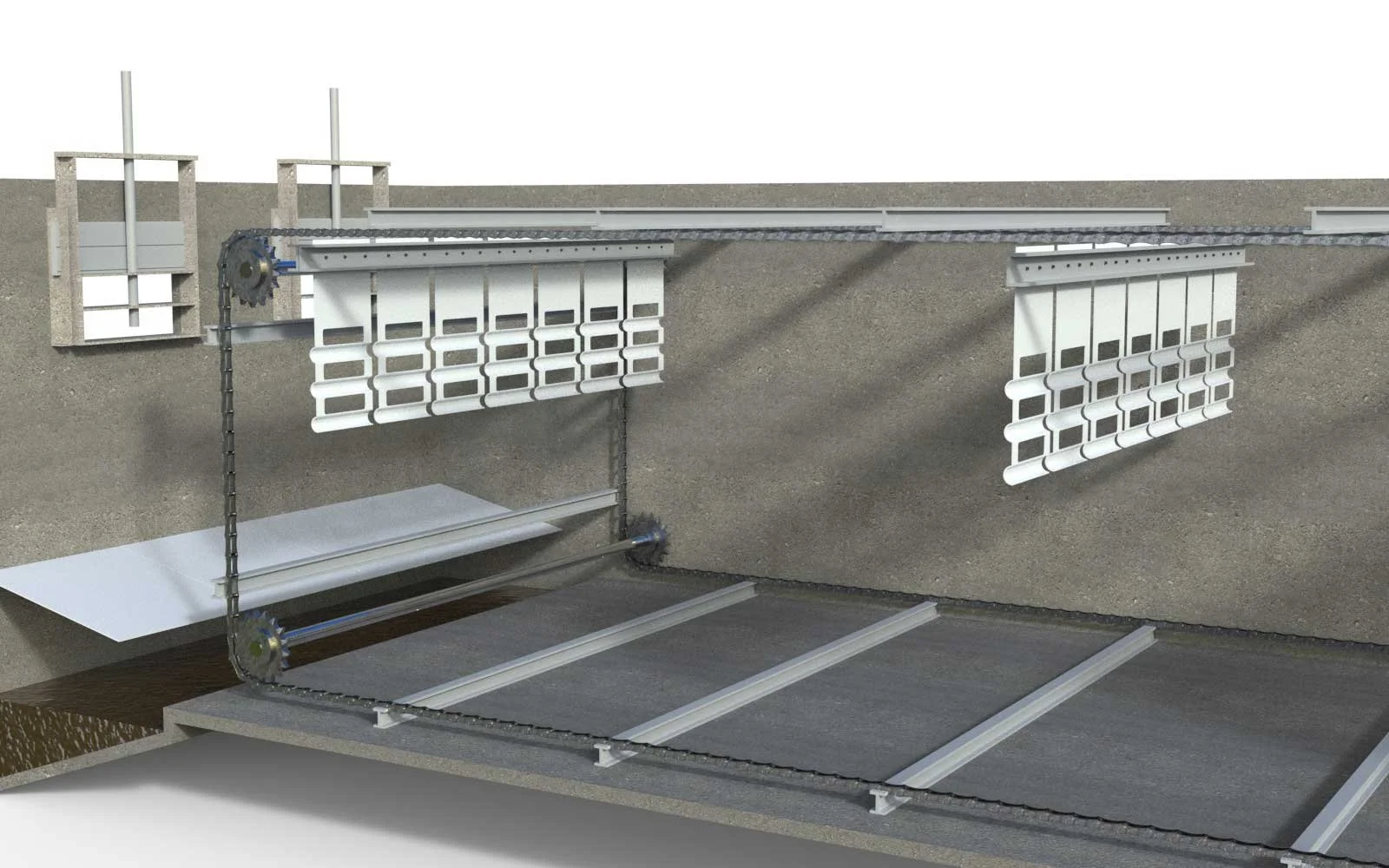

Our firm’s focus is analyzing and optimizing internal clarifier hydraulics. We use computation fluid dynamics (CFD) tools to identify flaws and design specialized baffle systems to enhance flocculation, protect settled sludge, and improve the transition into the settling zone.

-

1. Increased capacity during wet weather

2. Increased primary solids capture for aeration energy savings

3. Improved final effluent quality

4. Reduced capital program costs

The patented baffle systems we design and supply benefit from 20 years of installation experience and over 225 installations worldwide.

-

Although most primary sedimentation and secondary clarifiers can be improved, the best candidates include primary sedimentation and secondary clarifiers with:

- Rectangular Geometry

- Shallow Sidewater Depth (less than or equal to 12 feet)

- Circular Geometry Constructed before the year 2000

- High wet weather peaking factors

- High mixed liquor concentrations

- Or when a plant expansion is planned

What is Possible for Your Plant?

Optimization can lead to the elimination of planned expansions, significant increases nameplate capacity, and improved primary and secondary effluent quality.

Typical results are a 25% reduction in primary of secondary effluent solids. If improved solids are not the goal, a similar improvement (25%) in nameplate capacity can be achieved. There are many examples where actual results exceeded typical values. Taking initial steps to evaluate optimization can uncover these bigger opportunities.

Rectangular primaries are great candidates and can be made to double their capacity while improving solids capture efficiency.

Optimization is not right for all plants. To determine if your plant is a candidate, we work collaboratively through the following steps.

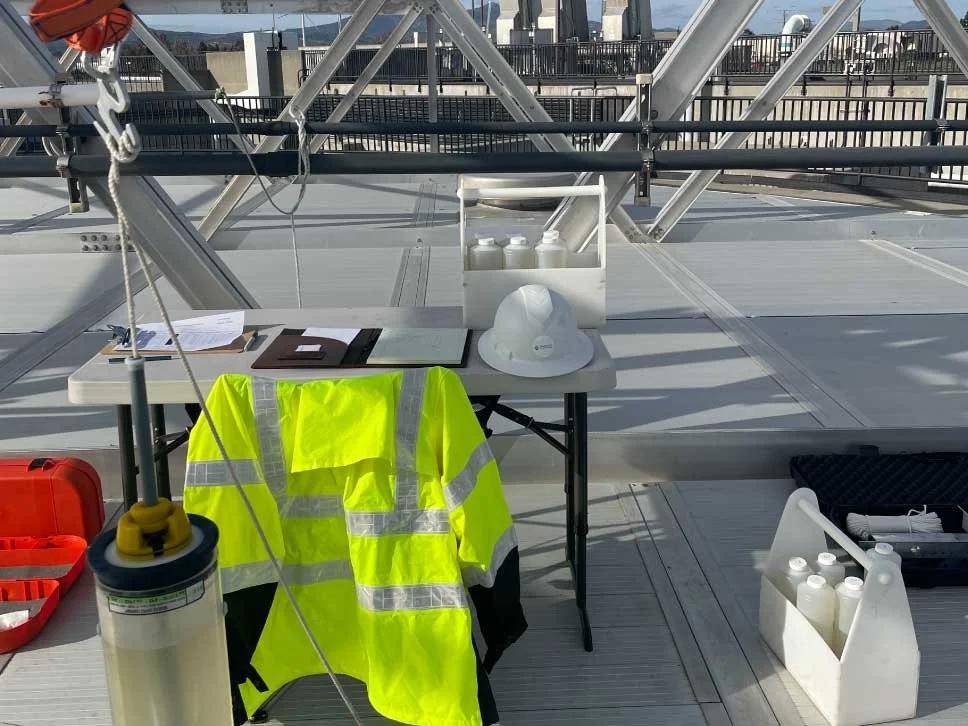

Review available process data and clarifier drawings. Prepare an initial estimate of likely improvement. (no cost)

If warranted after Step 1, develop a plan for field testing and/or CFD Modeling to quantify the expected improvements.

Do you want an estimate of optimization benefits for your treatment plant? Contact us to start a conversation.

25%

The technology use led to a 25% increase in primary solids capture at Central Contra Costa Sanitary District (Martinez, CA)

Wastewater Optimization Results

48%

48% increase in primary solids capture and elimination of two planned primary sedimentation basins from Dublin San Ramon Services District capital plan (Pleasanton, CA)

2x

2X increase in wet weather capacity (3000-6000 gpd/sf) while improving solids capture by 43% (LOTT Clean Water Alliance - Olympia Washington)

37%

37% increase in primary solids capture efficiency at the Annacis Wastewater Treatment Plant - (Metro Vancouver, BC)

70%

70% Increase in primary clarifier capacity identified by field testing and CFD modeling - Fairfield Suisun Sewer District (Fairfield, CA).

Wastewater Optimization Projects

Testimonials

-

"The baffle systems led to a 50% increase in primary solids capture and a 20% increase in biogas production. I would give the results an A++"

Jeff C., Wastewater Operation Director - Dublin San Ramon Services District

-

"We installed the Floclip system on our secondary clarifiers in 2014. The effluent from our secondaries typically bounces between 1-2 NTU. Very pleased with the performance."

Larry P., Wastewater Plant Supervisor - City of Vacaville

Our Mission

Our Mission is to help wastewater professionals get the most out of their primary sedimentation and secondary clarification processes. We use simple, passive technologies to enhance capture efficiency leading to lower electricity costs, increased biogas, and higher effluent quality.